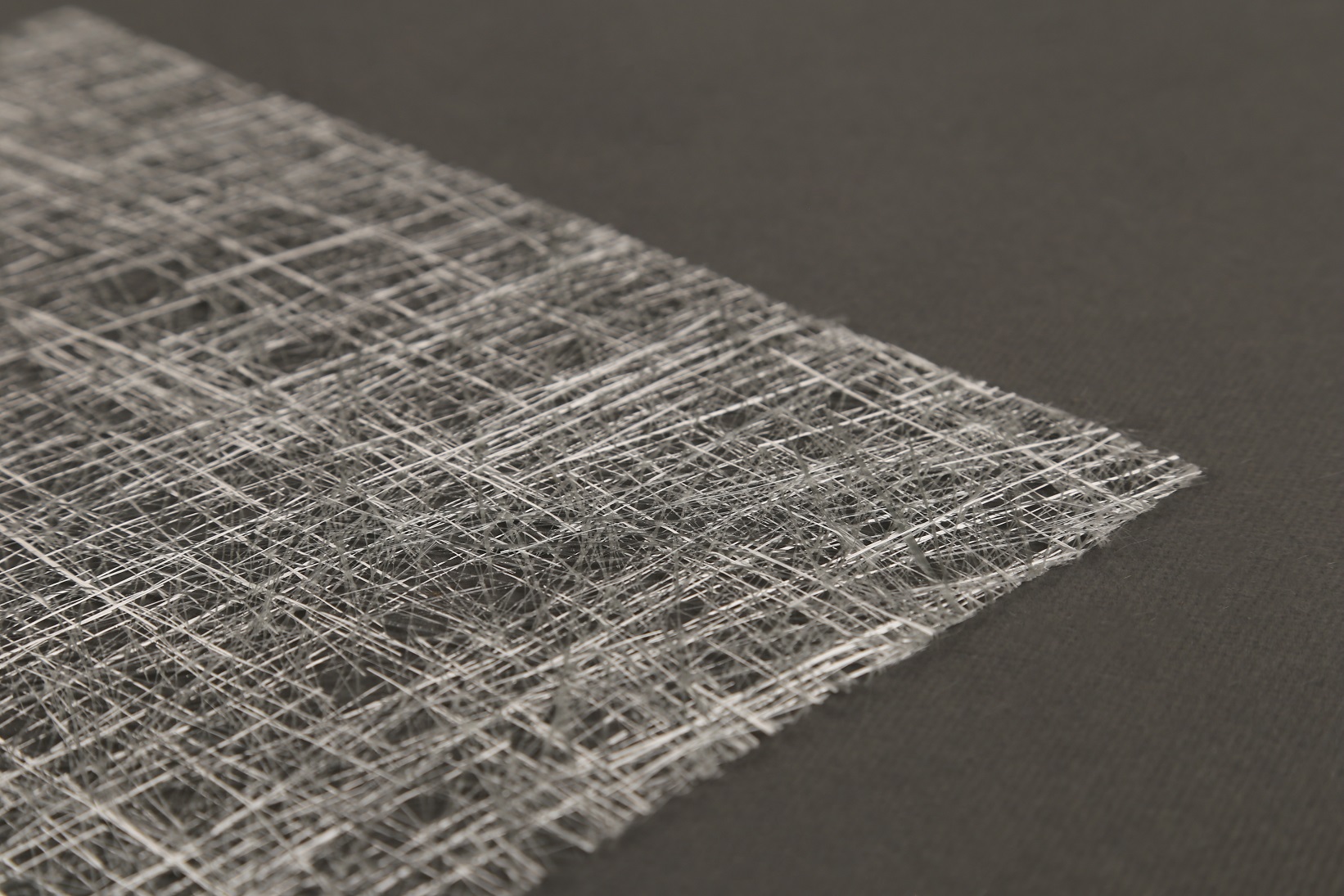

Chopped Strand Mat – Emulsion Binder

Chopped Strand Mat is typically used in the composite industry for boats, tanks, silos and panels, as well as large structural parts in transportation, construction and other industrial applications. It is characterized by rapid wetting and dewetting and easy air release, thanks to its optimized chemical and physical properties.

| Unit Area Weight | 100-800 g/m2 |

|---|---|

| Binder | Emulsion |

| Roll Width | 50 – 300 cm |

| 1m Roll Weight | 30 & 40 kg |

Reviews (0)

Related products

Woven Roving

Woven Glass Fiber Roving is a bi-directional fabric made with interwoven roving and compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins. This fabric is used in manual laying and robot automation processes of FRP products such as boats, ships, automotive parts, architectural structures, etc. The characteristics of Woven Glass Fiber Roving fabric are low fluffing, fast wetting ability, equal thickness and high mechanical strength.

| Unit Area Weight | 300 - 1000 g/m2 |

|---|---|

| Type | Plain |

| Roll Width | 20 - 300 cm |

| 1m Roll Weight | 40 kg |

Combo Mat

Glass Fiber Combo Mat, Combo Mat is a new product from RSC, consisting of two layers of Glass Fiber, one chopped strand mat and the other woven roving, justifying its name. This product is used with polyester, vinyl ester, phenolic and epoxy resins, especially in manual lamination, plating and RTM applications. This product is used in FRP boats, automotive industry, laminates, coolers and buildings.

| Unit Area Weight | 400 - 1500 g/m2 |

|---|---|

| Type | Woven and Felt |

| Roll Width | 1 - 3 m |

| Roll Length | 30 - 50 m |

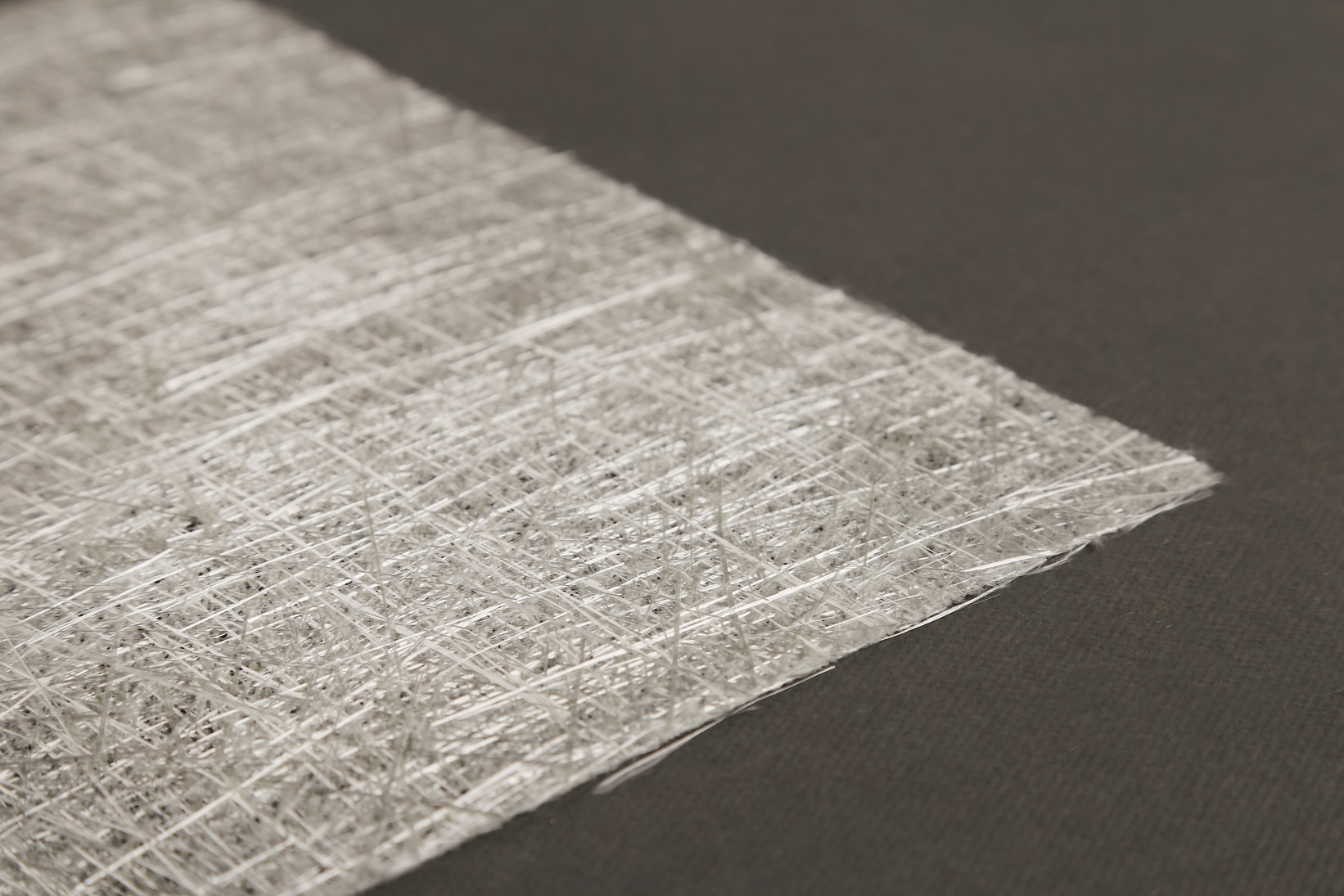

Chopped Strand Mat – Powder Binder

Chopped Strand Mat is typically used in the composite industry for boats, tanks, silos and panels, as well as large structural parts in transportation, construction and other industrial applications. It is characterized by rapid wetting and dewetting and easy air release, thanks to its optimized chemical and physical properties.

| Unit Area Weight | 100-800 g/m2 |

|---|---|

| Binder | Powder |

| Roll Width | 50 - 300 cm |

| 1m Roll Weight | 30 & 40 kg |

Surfacing Tissue

Glass Surface Tissue is the outer layer of glass fiber reinforced plastic (FRP). Uniform distribution, low absorption, rapid saturation of resin, soft surface and easy shaping are the most important features of this texture. This kind of texture can increase the external tension of FRP, increase the resistance to pressure and make the outer surface even and wear-resistant. This product is normally produced in 30g per square meter and cut into 45mm width, wrapped on 3cm hard paper tubes.

| Density | 28-30 g/m2 |

|---|---|

| Roll Width | 4.5 cm |

| Roll Length | Max 500 m |

Reviews

There are no reviews yet.